Digital Services @ Epiroc

With today’s disruption from Covid and the economic downturn, continuing services innovation is paramount to survive and thrive. Customer needs are...

8 min read

Jan van Veen

Oct 18, 2020 3:37:41 PM

Manufacturing companies have a tremendous opportunity to grow and thrive through digital services if they escape from business-as-usual. For most manufacturers, the growth will come from other digital services than predictive maintenance or remote services. There are many different types of digital services. In this article, I describe the 8 different types of digital services which can help you and your teams grow your service business and thrive.

Digital transformation and digital services have been a hot topic for a while in most manufacturing industries. Besides the various technologies, like AI, smart glasses and digital twin, most dominant topics today still seem to be predictive maintenance, remote diagnostics and remote resolution.

There are many more types of digital services that solve other customer problems, which have more potential to grow your business and help you thrive in these disruptive times.

Manufacturers run the risk of being stuck in business-as-usual, falling behind the competition and new entrants and ultimately miss out on today’s opportunities. That is why the moreMomentum Services Community captures, shares and applies new best practices of digital services and radical business innovation. This article is part of a series of articles about Digital Services by Manufacturers.

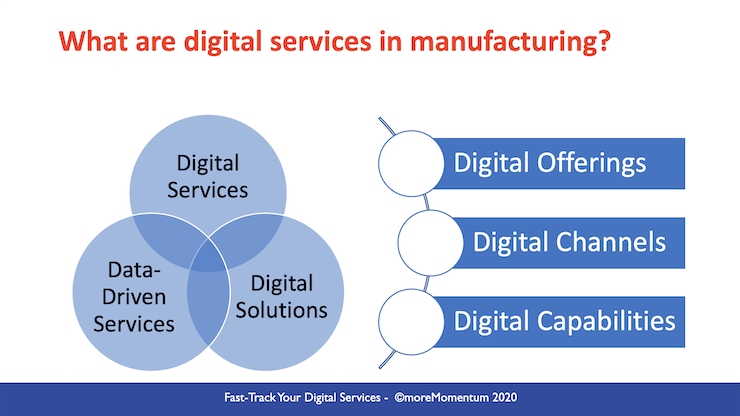

Digital services in manufacturing are solutions to your clients’ problems which involve one or more of the following elements:

In this article, I will focus on 8 different types of digital offerings.

Equipment is often enhanced by software for additional functionality, automation and control to improve the way it functions and performs. The result could be fewer incidents, higher efficiency, reduction of energy usage, lower consumption of consumables etcetera.

These functions can run on board of the equipment or in the cloud.

Most often, these innovations address the expected next step improvement in an industry, which are being pursued by most manufacturers in that industry. It’s all part of the dominant logic in the industry. Hence, these are sustaining innovations which often may be required to defend your market position and your “license to operate”.

Although these digital solutions are not a service, they can have an impact on the expected services like:

By using more automation, data, connected assets and remote support, you can increase the effectiveness and efficiency of maintenance:

By using more automation, data, connected assets and remote support, you can increase the effectiveness and efficiency of maintenance:

This is the type of digital services many manufacturers are working on and have the dominant focus on when it comes to digital services.

In essence, there are two major driving forces in play here:

The name of the game is simplifying maintenance through smarter maintenance and enhanced serviceability of the equipment.

In most industries, this will be a sustaining innovation, following the expected journey of continuously improving uptime and reducing cost. The service-fees will most likely decrease in time – not increase.

With sensors, location trackers, software and networking, you can provide useful data and actionable information to the asset-owners or users about:

With sensors, location trackers, software and networking, you can provide useful data and actionable information to the asset-owners or users about:

This can be offered through a hosted dashboard which sends actionable notifications. It could also be a data-stream into your clients’ ERP-system, where further processing and algorithms take place, together with many other data from other equipment and data sources.

More than the first 2 types of digital services above, the value proposition is significantly expanding from only providing good equipment in good condition towards helping customers to improve productivity, efficiency, utilisation and risk-reduction. These services solve other customer problems, which have different owners in your clients’ organisations. It will also involve a closer collaboration with clients, integration of operations of clients and service providers.

This will have a significant impact on your:

Most manufacturers already have some sort of customer training for operators, users and maintenance departments. You can expand the scope of your education services to address your clients’ challenges like:

Most manufacturers already have some sort of customer training for operators, users and maintenance departments. You can expand the scope of your education services to address your clients’ challenges like:

Education in general is going through a major shift at the moment. People have been changing the way they learn and solve problems using all kind of sources and media at their fingertips.

This is a vast domain in itself. A few important trends are:

In essence, training and education are shifting to online, remote and becomes more data-driven to increase effectiveness and efficiency.

Based on data coming from the truck’s sensors, other data like weather, historical data from the truck and the truck driver, MAN Trucks offers live training in the truck cab in order to:

The value for fleet owners is fuel savings, reduction of CO2 emissions, lower maintenance cost, fewer accidents, no downtime of drivers due to training.

The effort and investment in developing advanced training content and methods and in staying up to date will increase.

There is a serious opportunity for growth of revenue streams, customer experience and loyalty as many clients need new competencies and capabilities for their new ways of working.

One of the significant impacts of digitalisation is that your clients are going through a transformation. Their operational, tactical and strategic decisions are becoming more data-driven. This affects any business function, like supply chain, marketing, sales, asset management, maintenance, service delivery, manufacturing, R&D and finance. Your clients will be building the necessary capabilities and will be looking for new solutions and services to build these capabilities or outsource part of the capabilities.

As a manufacturer, you can play a role for your clients in their endeavours to optimise operations, reduce waste and more.

As these kinds of service emerge, the impact is significant:

This is a unique opportunity to enrich your value proposition, expand your customer value and generate new value streams to thrive in the future.

The last decade we have seen quite a few market disruptions coming from new digital platform-offerings which provide easy and high-volume access to – and interaction with – the market, solution providers and peers. This involves connectivity of things, software, data, people and businesses.

The last decade we have seen quite a few market disruptions coming from new digital platform-offerings which provide easy and high-volume access to – and interaction with – the market, solution providers and peers. This involves connectivity of things, software, data, people and businesses.

For most manufacturers and service providers, the solutions they provide are not complete solutions for a more significant customer problem. Alone, these offerings do not solve the problem and hence do not add value. For example:

A few of the opportunities could be to:

The digital transformation is a significant challenge for any business. Also for your clients. It does not only involve rapidly changing digital technology and industry-specific proprietary technology. It also affects their processes, people, operating model, business model, strategy etcetera.

The digital transformation is a significant challenge for any business. Also for your clients. It does not only involve rapidly changing digital technology and industry-specific proprietary technology. It also affects their processes, people, operating model, business model, strategy etcetera.

This is a unique opportunity for existing consultancies a new niche-consultancies. Also, manufacturers have the opportunity to offer their internal development and consultancy capabilities to their clients.

The opportunity is to become a trusted advisor and build deep customer relationships with multiple stakeholders in your client’s organisations. Also, it will help to position your company as a thought leader, making your brand more attractive and improving your position to partner with other (new) players in a rapidly changing industry. When well-managed, these activities can be at least financially self-supporting, if not profitable.

Product-as-a-service offerings are often seen as the holy grail of any servitisation-journey. These are services offering your clients the value from a product without them having to own and operate the product themselves. They outsource (part of) the operations around the product.

This is much more than financing the product combined with smart maintenance services, supporting your client to shift from CAPEX to OPEX.

In some industries, the market is increasingly asking for these kinds of managed services. It radically changes the overall value proposition, business model, operating model and financial model of a manufacturer.

Digital services in manufacturing are much more than predictive maintenance and remote support. There are many opportunities to extend the types of customer problems you solve and to enhance your value proposition and business model. The big opportunity to grow your business and thrive during the digital and disruptive transformation is beyond the predictive maintenance and remote support offerings.

However, launching new smart maintenance and support offerings probably is critical to maintaining your position in the market and your license to operate.

In today’s digital disruption and economic downturn, the leading manufacturers that thrive will be adopting a broader range of digital services, enrich value proposition and business model. Leaving those stuck in a transactional product-centred approach behind, wondering how the leaders did it.

Which brings me to the question: With which digital services will you grow and thrive?

Subscribe for the our Impulse Letter

With regular updates about service news, trends and best practices.

With today’s disruption from Covid and the economic downturn, continuing services innovation is paramount to survive and thrive. Customer needs are...

Navigating data-driven service transformation requires overcoming key challenges such as securing stakeholder buy-in, matching services with market...

In a dynamic business landscape like in services for manufacturing companies, strategic thinking is a necessity. Cultivating this skill across all...